MICROBIAL INACTIVATION BY MICROWAVE TREATMENT

recognized and recommended by the WHO

MICROBIAL INACTIVATION

INNOVATIVE PATENTED TECHNOLOGY

The Sterilwave solution has been specifically designed to provide a bespoke on site facility suited to individual hospitals or an NHS Trust with a number of hospitals within their region. Our solution for compliantly treating biomedical waste is based on a combination of shredding by speed controlled rotating blades and controlled temperature rise using microwave technology. 100% electrically powered, this innovative patented technology allows microbial inactivation of medical waste in 35 minutes. Compared to traditional merchant plant solutions, which consume high amounts of energy (generation of steam / water / electricity / treatment of effluents/ external pre/post shredding) and mostly requires the management of a process under pressure or at temperatures exceeding 1150degC, our Sterilwave solution reduces these safety risks, makes sure your CW stays on your site until it is sterilised and leaves you with an RDF flock categorised as EWC 191210. Our technology is designed to fit in small spaces, to service its own hospital site, it is controlled by a PLC and only requires non technical personnel to operate the facility. Their maintenance is simple and low cost compared to competing technologies. Processing cost per tonne is highly competitive and it allows the client to control their own treatment costs over a 10 year period or longer if required.

All types of EWC 180103 and EWC 180104 clinical waste in the form of solid, liquids, plastic, glass, metal, textiles, blades, etc.) can be treated by the Sterilwave system. Besides the efficient and rapid decontamination of waste with a microbial inactivation level of up to 8 log10 (higher than the required sterilisation level) on a stable and fully automated cycle of 35 minutes, Sterilwave also makes it possible to convert biohazardous waste into a dry and unrecognisable and sterile RDF with a categorisation of EWC 191210. The process reduces weight by more than 25% and volume by 80%. This resulting material best described as a flock with particle sizes between 5mm and 20mm can also serve as energy-efficient secondary fuel to EFW’s with a typical CV of 16MJ/KG.

Treats clinical waste on producer site. Highly Efficient . Cost Effective . Safe . UK and International Safety Record. Compliant. Reduced CO2 footprint and HGV traffic. Effective.

MICROBIAL INACTIVATION

THE PROCESS

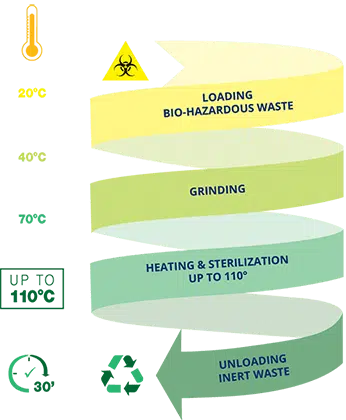

Through a fully automated 30-minute cycle in one single vessel and a rapid and efficient temperature rise up to 110 ° C, Sterilwave transforms infectious waste into decontaminated municipal waste.

Efficient: microbial inactivation up to 8log10

Compliant with all international standards

Safe: no irradiation risk, no pressure on the vessel, no chemicals

Eco-friendly: 100% electric

No water, no liquid effluent, circular economy possibilities

Adapted to any type of medical waste without specific segregation

Plastics, sharps & needles, blood bags, textiles, anatomical waste …

Low operating cost, easy maintenance

Low energy consumption, low maintenance cost, one of the lowest operating costs on the market

RANGE OF EXPERTISE

IN COMPARISON

Incineration has been the most widely used method for treating infectious waste. However, biomedical waste incinerators release a wide variety of pollutants in the air, including organic compounds such as benzene, chlorophenols, polycyclic aromatic hydrocarbons (PAHs), vinyl chloride and dioxins, heavy metals (mercury, arsenic, cadmium, chromium, lead, etc.), acid gases (hydrogen chloride, hydrogen fluoride, sulfur dioxide, nitrogen oxides), carbon monoxide, and particulate matter such as fly ash. Pathogens can also be found in the solid residues and exhaust gases of poorly designed and poorly used incinerators.

For the treatment of solid biomedical waste (and liquid waste packaged in suitable packaging / containers), there are alternative heat treatments so-called “low temperature” incineration by dry or humid heat. These decontamination technologies must be combined with mechanical methods such as shredding or crushing, to destroy pathogens. The shredders improve the rate of heat transfer and expose more waste surface for processing.

As it uses the microwave technology, Sterilwave is the easiest, most efficient and economical solution to manage medical waste onsite.

| Waste management method | No specific construction required |

No polluting emissions |

|||||

|---|---|---|---|---|---|---|---|

| Dry | Stable | Sterilized | |||||

| STERILWAVE | |||||||

| Autoclave | Some models | Some models | |||||

| Incineration | |||||||

| Chemical treatment | Some models | Some models | |||||

As it uses the microwave technology, Sterilwave is the easiest, most efficient and economical solution to manage medical waste onsite.

| Technology | Temperature under pressure over 130 °C Require a steam-powered generator | Incineration on specific location. Require special carrier (expensive) | Based on microwave technology, simple and efficient (heating at 100°-110°C) More efficient than Autoclave technology ( confirmed by WHO) |

|---|---|---|---|

| Pressure / authorization Risk in case of error | Working under pressure (several bars of saturated steam); Specific authorization to work under pressure; Require many maintenance tasks; High risk in case of human error |

NC | Ambient pressure Safe to operate and maintain Limited Risk in case of Human error |

| Integrated grinding system | Slow shredding <20 mm output size | No | Yes by rotate blade: 1500 RPM <10mm output size |

| Disinfection efficiency | from 5 log to 8 log10 (depending the brand model) | Complete destruction | Up to 8 log10 more than 6 log 10 for virus |

| Output Waste after treatment | Volume reduction up to 80%; Wet waste; Increase of the weight 20% due to water and steam |

Complete destruction Ashes | Volume reduction up to 80% Dry Waste Weight reduction of 25% Easy to recycle |

| Operation cost | Cost for energy, water, spar parts and consumables | Cost for Energy, filters, maintenance | Lowest running cost for consumables, energy and maintenance |

| Environmental impact | Medium Require important volume of water Liquid effluents |

Negative Pollution Special carrier of ashes always requested POPs, Toxins |

Positive On-site waste treatment No effluents Volume and weight reduction of the treated waste Only require electricity |

MICROBIAL INACTIVATION

OUR PRODUCTS

Sterilwave 440

The Sterilwave 440 is the ideal treatment solution for institutions producing a large quantity of biomedical waste, as it can treat 88kg/hour* with minimal operating costs. View Product

Sterilwave 250

With a waste treatment capacity of 50 kg per hour, the Sterilwave 250 allows medium-sized institutions to treat their biomedical waste, guaranteeing safety and traceability at greatly reduced operating costs. View Product